The State Mints of Baden-Wuerttemberg is Germany’s largest mint, with a total of 80 employees at two sites. The two mints are owned by the regional government of Baden-Wuerttemberg and are responsible for striking 40% of Germany’s euro coins. In Karlsruhe and Stuttgart state-of-the-art technology is used to produce euro circulation coins, German commemorative coins, medals, and coins and medals on behalf of central banks from all over the world. The State Mints of Baden-Wuerttemberg are therefore among the world’s leading coinage producers.

Coins for Germany

and beyond

% of Germany's circulation coins

% of Germany's collector’s coins

28

minting presses

20 minting presses for circulation coins

We have 13 vertical and 7 horizontal Schuler coin minting presses at our disposal. With each press we strike 750 coins per minute or 45,000 coins per hour, achieving a grand total of 360,000 coins per eight-hour shift. We have a total average capacity of 15,000 coins per minute or 1.2 billion coins per year.

7 minting presses for commemorative coins

All seven of our Graebener minting presses for commemorative coins are located in coining halls offering a “clean-room environment”. In an eight-hour shift, we are able to produce between 3,000 and 5,000 coins in proof quality.

7 minting presses and one oil-hydraulic press for medals

We can produce medals with a diameter of up to 40 mm on the seven Graebener presses. We have an oil-hydraulic press from Sack & Kiesselbach at our disposal for medals with a larger diameter or a particularly high relief.

coins per minute

coins per year

coins per minute

coins per year

© Schuler Pressen GmbH

All in the name of polymer coin production

Are you thinking of adding the new polymer coins to your suite of denominations? You’ll be surprised by the benefits this new development can offer in anti-counterfeiting prevention and cost efficiency. We shall be delighted to advise you.

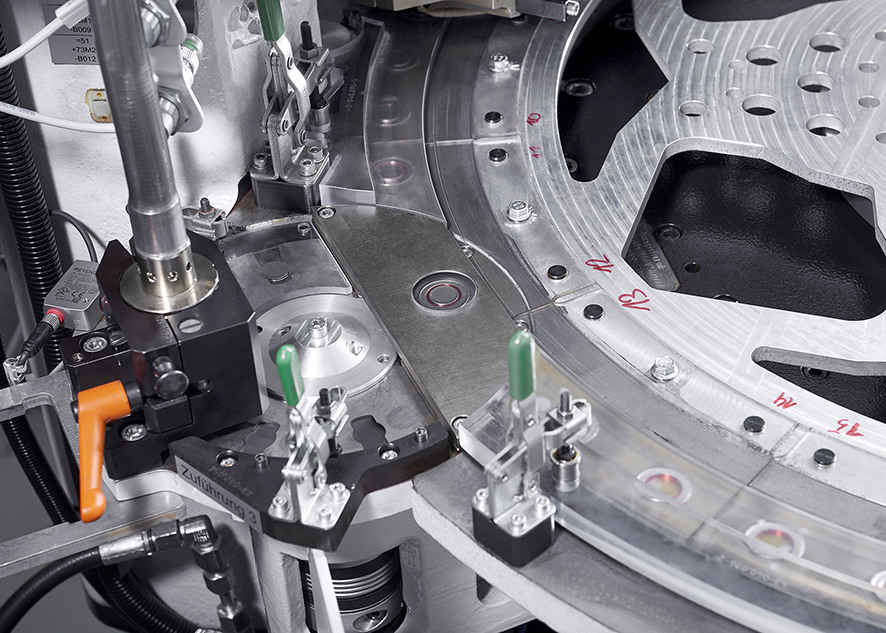

At our disposal we have all the technical equipment needed to join and mint the bi-metallic blanks with the polymer ring.

Apart from the Bavarian State Mint [Bayerisches Hauptmünzamt], the State Mints of Baden-Wuerttemberg are currently the only mint permitted to join polymer blanks.

Setting a benchmark in packaging

In Stuttgart, we have a fully automated packaging line with built-in quality control for coin sets and proof commemorative coins. Each day between 7,000 and 8,000 commemorative coins can be placed in the capsule and packaged. Thanks to a sophisticated optical system, deviation is limited to +1/-1°.

We have three packing lines to process circulation coins. During each shift, we can handle up to 5 million coins per packing line. We offer various packaging options for this procedure: coin rolls in foil, coin rolls in cardboard box, or loose in bags.